In House Mouldshop

Excellence in Mouldmaking

More then 35 years of experience in making

moulds for different type of industries...

a Belgian family business with a tradition of excellence in mouldmaking. Boasting over 35 years of experience, we specialize in crafting both injection moulds and extrusion blow moulds with unmatched precision and quality.

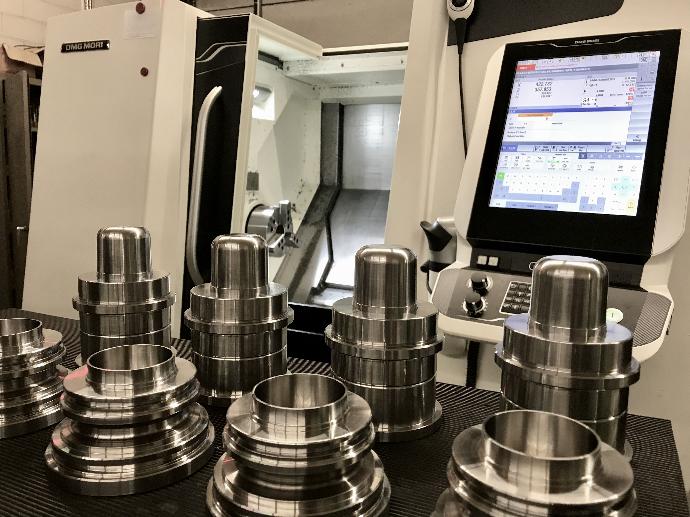

Our in-house mould shop is our pride, offering significant advantages to our production process. One of the key benefits is the elimination of production interruptions. Thanks to our dedicated team and facility, we can swiftly repair and maintain moulds, ensuring a seamless and efficient workflow.

Moreover, our foresight in maintaining a stock of spare parts means we're always prepared for any unforeseen circumstances, further minimizing downtime and enhancing our productivity..

Click on the buttom below or call us +32 52 42 33 19

Machine list of IIP

18 injection moulding machines

- Clamp closing force ranging between 25 up to 320 Ton.

- Arburg, Engel, Demag, Battenfeld, Tederic and Negri Bossi

-

1 extrusion blow moulding machine from GDK

*1 CNC Milling Machine DMG ECOMIL 635V

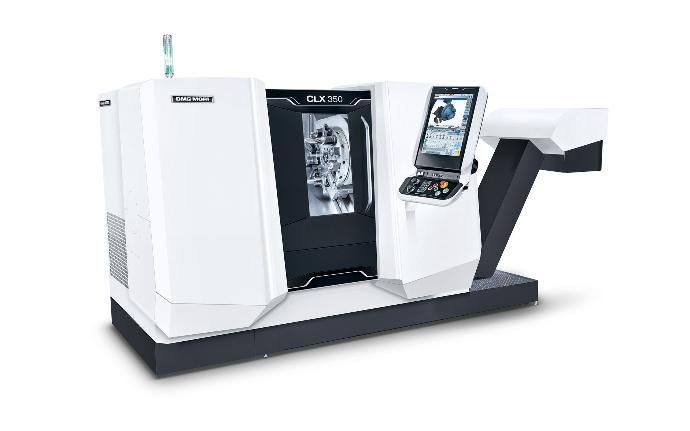

* 1 CNC- lathe DMG MORI CLX450

* 1 conventional lathe WEILER

* 1 CNC spark erosion machine CHARMILLES

* 1 surface grinding machine

* 1 surface grinding machine

-1 cylindrical grinding machine.

Printing techniques

- 3 round hot foil stamping machines + 1 flat hot foil printing machine

- 2-colour pad printing machine + UV full colour printing machine

- Screen printing machine for round parts.

-

Laser engraving machine

Assembling / Automation

Most of our machines are provided with SEPRO scara robots

- Multiple scara robots for assembling various range of products.

- 1 x Ultrasonic welding unit.

We have the passion and the knowledge to take your project from conception to completion.