Fabricant de pièces en plastique - Moulage par injection de plastiques

Injection de Plastique

Chez IIP, nous combinons notre longue expérience et notre savoir-faire en injection de plastique avec une approche axée sur le client. Nos technologies de pointe nous permettent de produire à la fois nos propres produits et des projets sur mesure répondant à vos besoins spécifiques.

- Nos Produits Développés en Interne

Nous proposons avec fierté une gamme de plus de 100 produits uniques, conçus et fabriqués par nos soins.

Ces produits sont disponibles et répondent aux normes de qualité les plus élevées. - Des Solutions sur Mesure pour Votre Projet

Avez-vous des exigences spécifiques ?

Nous travaillons sur mesure, transformant vos idées en un produit fini répondant parfaitement à vos attentes. - Divers Plastiques pour des Résultats Optimaux

Nous traitons une large gamme de matériaux de haute qualité, soigneusement sélectionnés pour leurs propriétés spécifiques et leur adéquation à diverses applications.

Voici quelques-uns des matériaux que nous utilisons :- PP (Polypropyène)

- HDPE (High-Density Polyethylène)

- LDPE (Low-Density Polyethylène)

- ABS (Acrylnitril-Butadieen-Styrène)

- PA (Polyamide)

- PC (Polycarbonate)

- PMMA (Polyméthacrylate de Méthyle)

Notre passion pour la qualité et la précision signifie que nous nous efforçons constamment de trouver les meilleures solutions pour chaque client.

Nous sommes heureux de vous accompagner dans chaque étape du processus, de l'idée au produit fini.

N'hésitez pas à nous contacter pour découvrir ce que nous pouvons faire pour vous !

Divers produits propres à IIP

Bouchons à vis

Nous produisons des bouchons à vis adaptés à diverses applications. Nos bouchons sont disponibles en versions avec ou sans bague d'inviolabilité, ce qui les rend polyvalents pour différents produits.

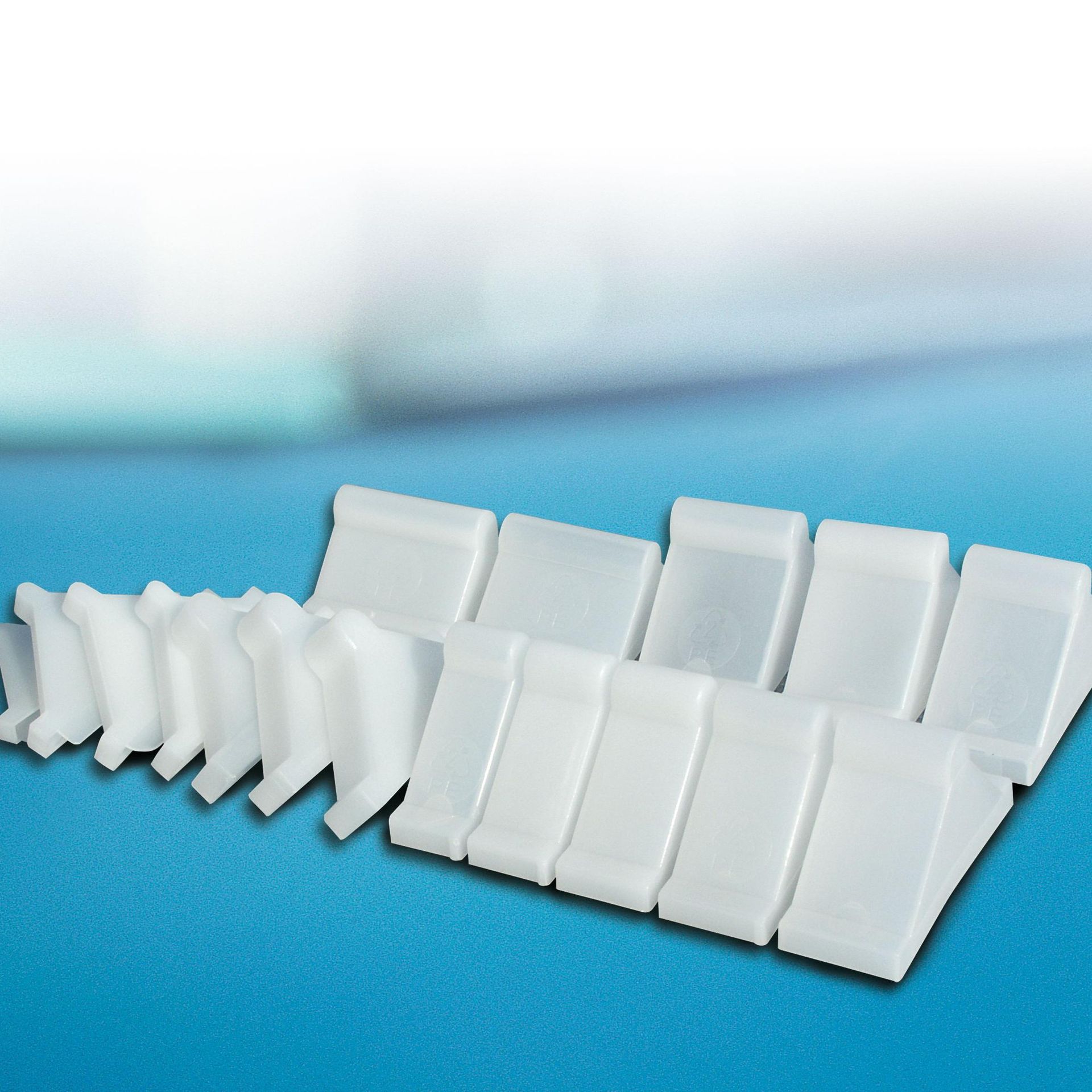

Coins de protection

Conçus spécialement pour l'emballage sécurisé d'articles fragiles tels que des miroirs et des plateaux de table. Ces coins de protection offrent une protection supplémentaire lors du transport et du stockage, réduisant considérablement le risque de dommages.

Pots pour cosmétique

Nos pots pour cosmétiques allient fonctionnalité et esthétique. Parfaits pour une large gamme de produits cosmétiques, ils sont fabriqués avec précision pour garantir qualité et durabilité..

Flacons en PE

Nos bouteilles en HDPE sont entièrement fabriquées en interne, avec des capacités allant de 50 ml à 750 ml. Nous proposons à la fois de petites quantités et des chargements complets selon vos besoins. Grâce à notre production interne, nous garantissons flexibilité et livraison rapide. Que vous ayez besoin d'une petite commande ou d'une grande livraison, nous assurons toujours des produits de haute qualité.